CLICK ON SUBTEAM ICON FOR MORE INFO:

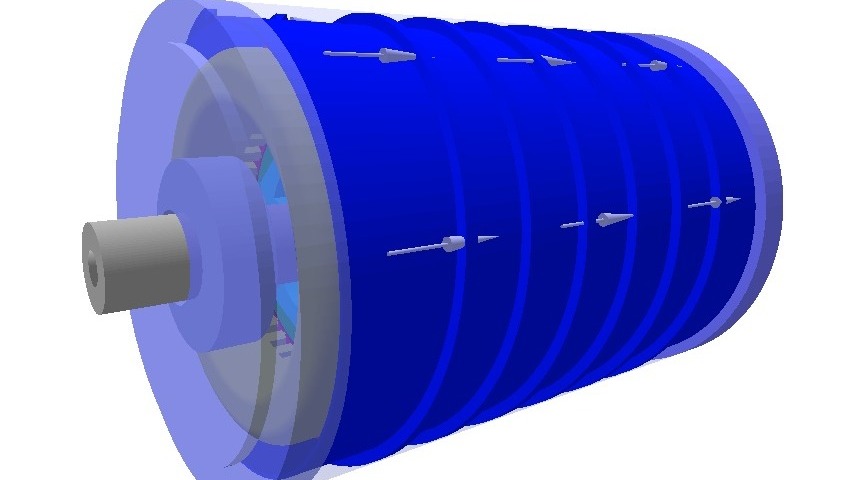

The second important task is the designing and manufacturing of the cooling system that is just powerful enough to keep the vehicle driving at race pace cool while remaining as lightweight as possible and meeting the restrictions of the Formula Student rulebook.

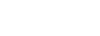

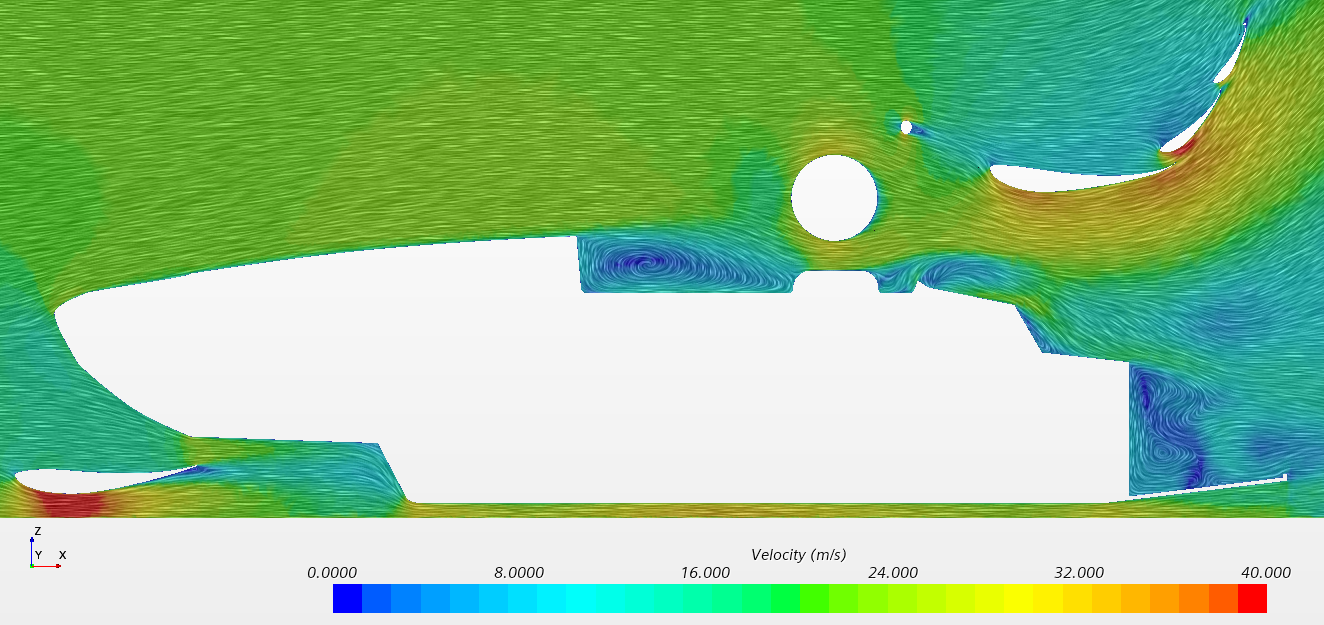

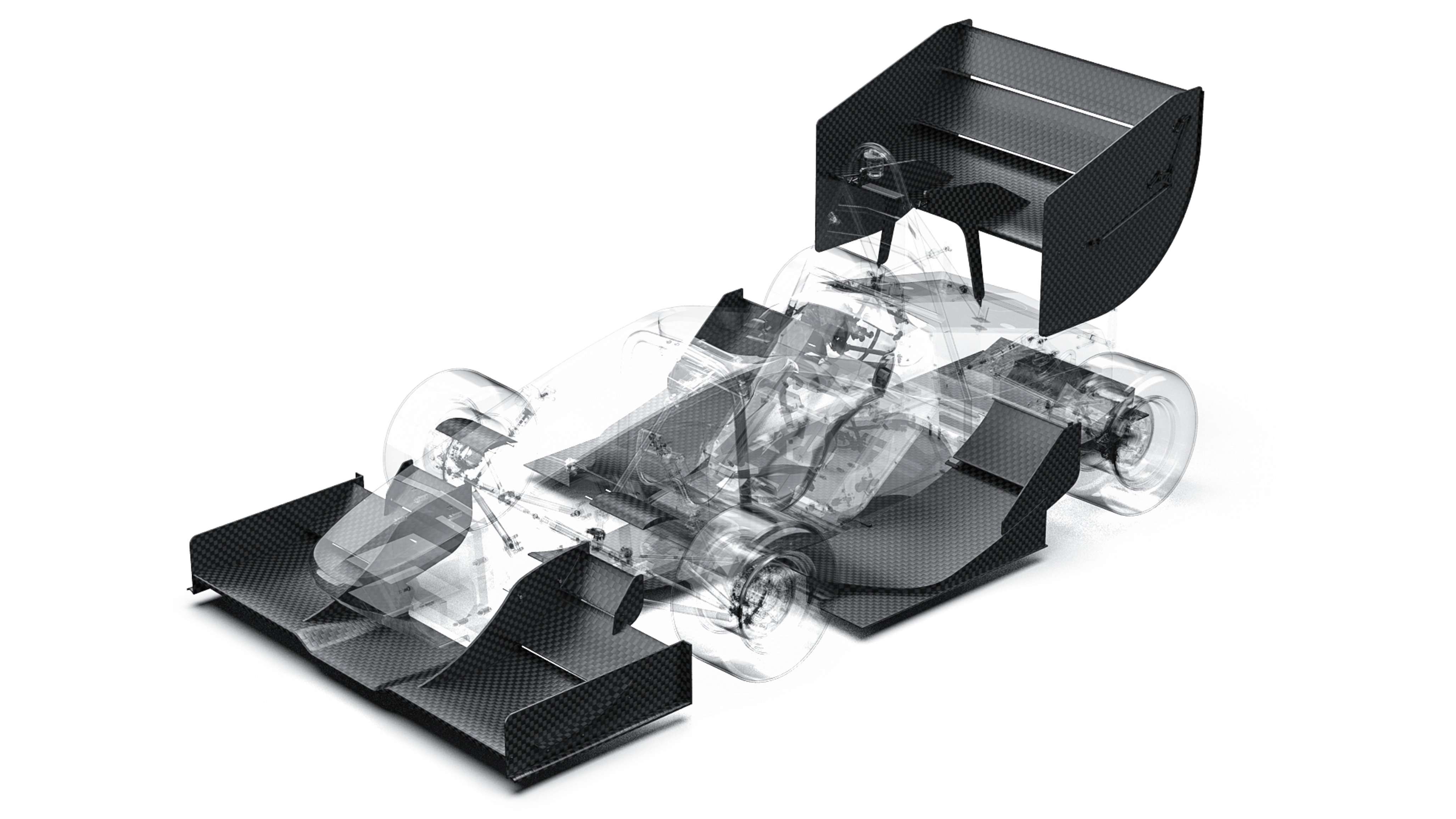

Sophisticated and industry leading 3D CFD (Computational Fluid Dynamics) simulations (together with 1D cooling loop simulations and structural FEM simulations) are used in the development phase to optimize our designs and extensive testing is performed to increase efficiency and reduce the mass of the finished aero & cooling package.

- Heat transfer & Fluid mechanics

- CFD

- CAD

- FEM

- Knowledge of material properties

- Knowledge of composites, cores, resin, etc.

- Innovation and creativity

- Organization

- Conceptual development of aero package (components and global assembly)

- Creating and modifying CFD simulation settings

- CFD component simulation, iteration of geometries based on analysis

- Geometry modelling for CFD simulations

- Post-process analysis of simulated geometries and decision making in the design phase

- Development of multi-element aerofoil sets for aero package components

- Optimizing cooling air flow

- Visualizing the results obtained from simulations

- Mapping the results obtained from simulations

- Thermodynamic calculations and one-dimensional simulations

- Development of cooling system components

- Development of heat exchangers for electric motor drive

- Development of load-bearing parts of packages

- FEA simulations of load-bearing parts of composite structures

- Manufacturing of composite structures

- MATLAB & Simulink

- Simcenter STAR CCM+

- SOLIDWORKS

- Abaqus

- Cad modelling

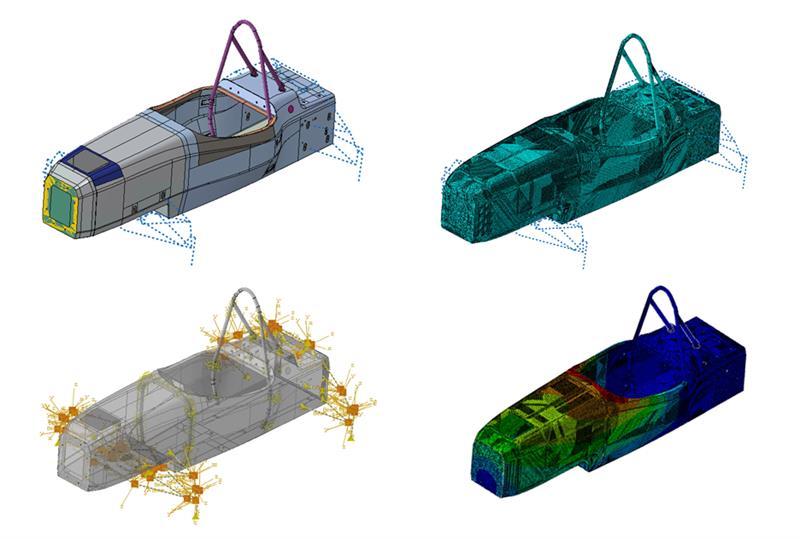

- Structural cae simulations

- Structural optimization

- Knowledge of composites material

- Composite laminating

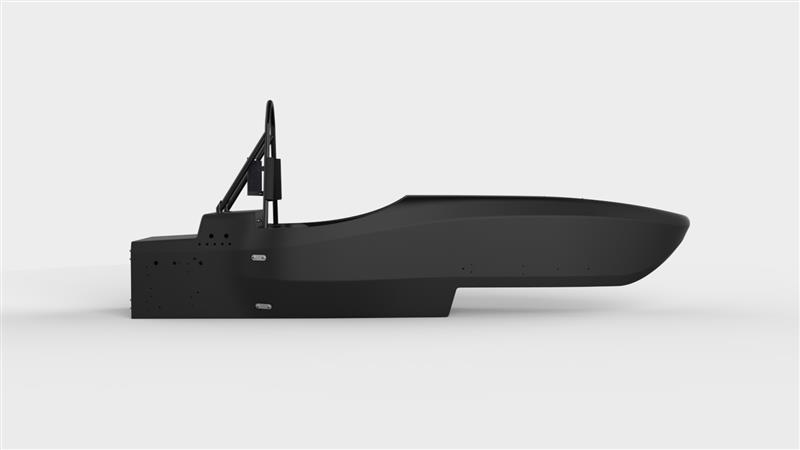

- CAD design of monocoque chassis

- Design of monocoque chassis moulds and moulds of composite parts

- Manufacturing of chassis and other composite parts

- Structural cae simulations and optimization of monocoque chassis and all structural composite parts

- Structural cae simulations and optimization of monocoque chassis and all structural composite parts

- Determining the layout of the monocoque chassis and composite parts

- Testing and validating materials and samples

- Conducting strength calculations of the monocoque chassis

- Impact attenuator testing

- Driver's ergonomy, design of the seat and steering wheel

- Solidworks

- Abaqus

- Hypermesh

- Optistruct

- Laminate tools

- MATLAB

- MS Office

The Control Systems subteam is mainly concerned with the development and integration of various estimation and control algorithms in the Vehicle Control Unit, with the aim of improving driving dynamics. Furthermore, the subteam is responsible for ensuring successful communication between all other control units in the vehicle and has the task of creating a telemetry system that enables live monitoring and maintaining safe operational state of the vehicle.

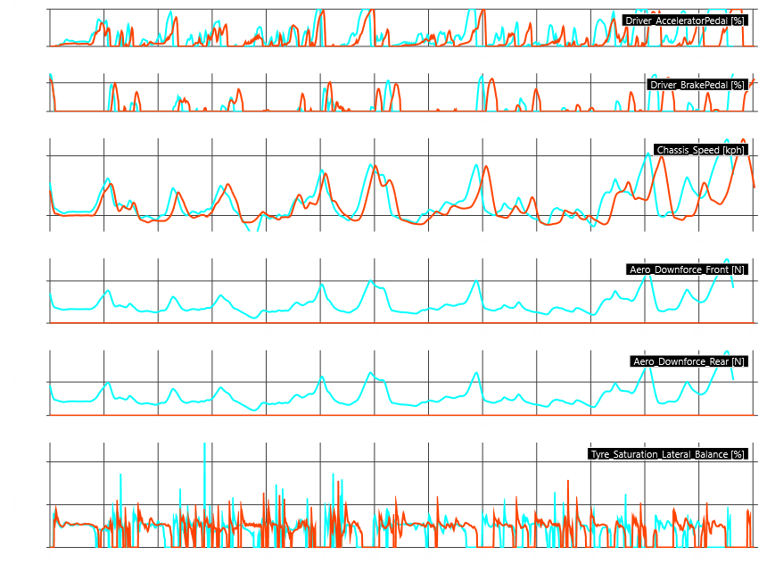

Vehicle dynamics subteam oversees the development and improvement of the whole vehicle’s performance. It starts from the concept phase and continues with deep simulation and development phase. This subteam also correlates and validates the vehicle model to see what was achieved and what to improve. Close cooperation with many other subteams is crucial for achieving the desired performance values.

- Control and Estimation theory

- Understanding vehicle Dynamics

- Electric vehicle architecture

- Electrical engineering

- Estimation and optimization theory

- Load analysis

- Teory of Mechanisms

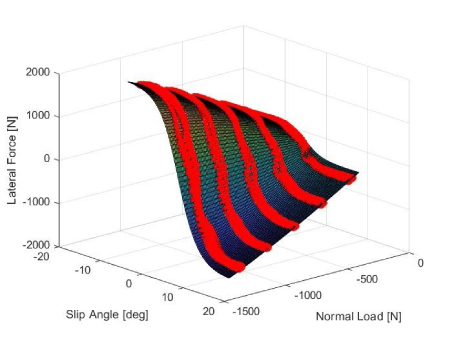

- Understanding Tire Model

- Race car drivetrain layout

- Understanding Vehicle Kinematics

- Development of vehicle dynamics control algorithms

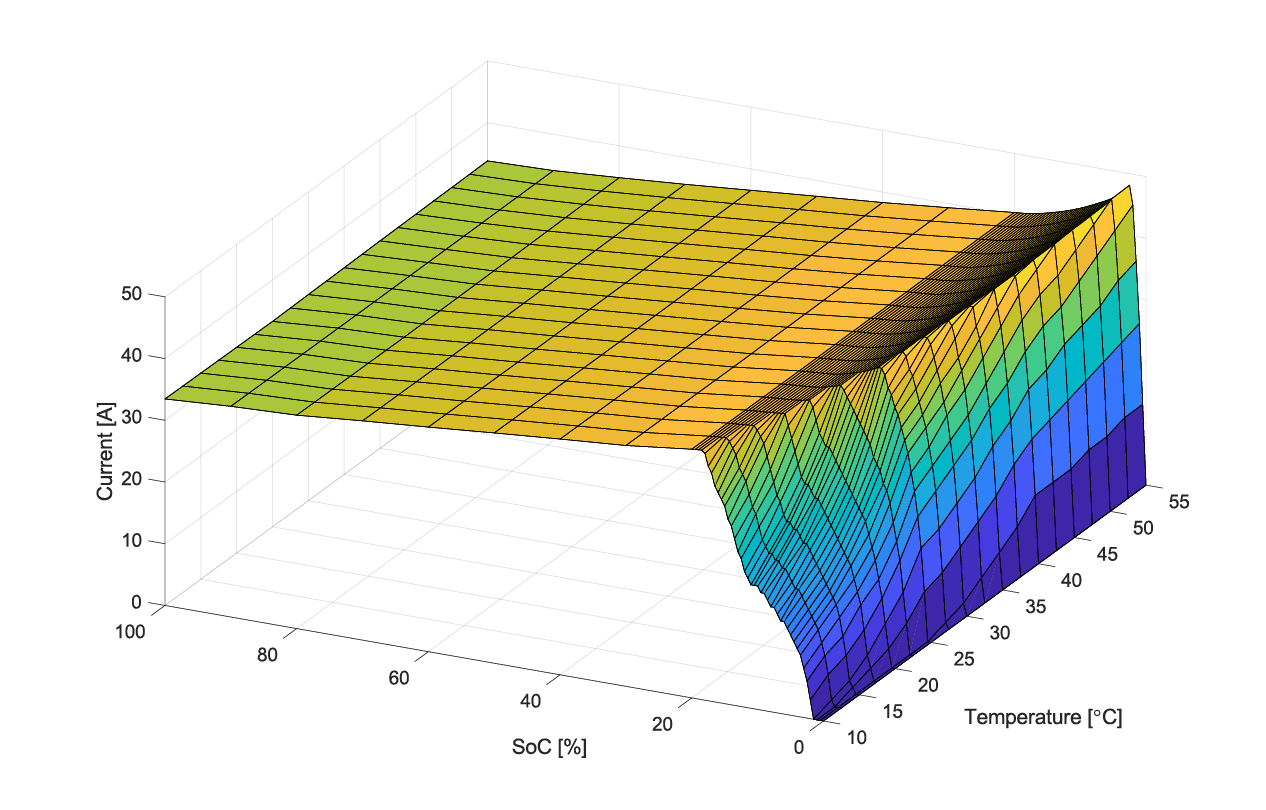

- Development of battery control algorithms

- Vehicle and battery state estimation

- Sensor data processing

- Vehicle state monitoring

- Integration of algorithms on Vehicle Control Unit

- Telemetry development

- Vehicle performance analysis

- Testing data processing

- Vehicle dynamics simulations

- Tire Modeling

- Vehicle layout and drivetrain concepting

- Modeling vehicle subsystems for simulation

- Vehicle validation and correlation

- MATLAB / Simulink

- AVL VSM

- PCAN-View/Vector CANalyzer

- MS Excel

- Linux / bash

- Python, C / C++

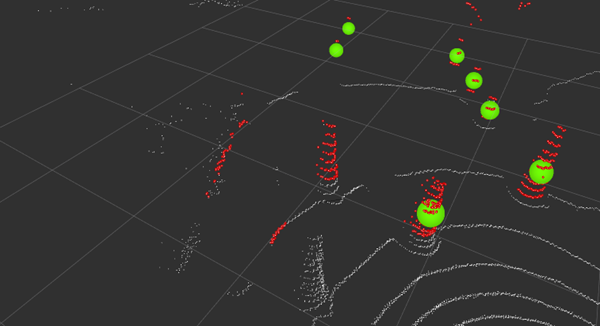

- Computer Vision

- Neural networks and Machine learning

- Probability and Statistics

- Control and Estimation theory

- Camera object recognition

- LiDAR point-cloud based object detection

- Simultaneous Localization and Mapping

- Trajectory optimization

- Vehicle motion planning and control

- ROS

- Gazebo simulator

- MATLAB / Simulink

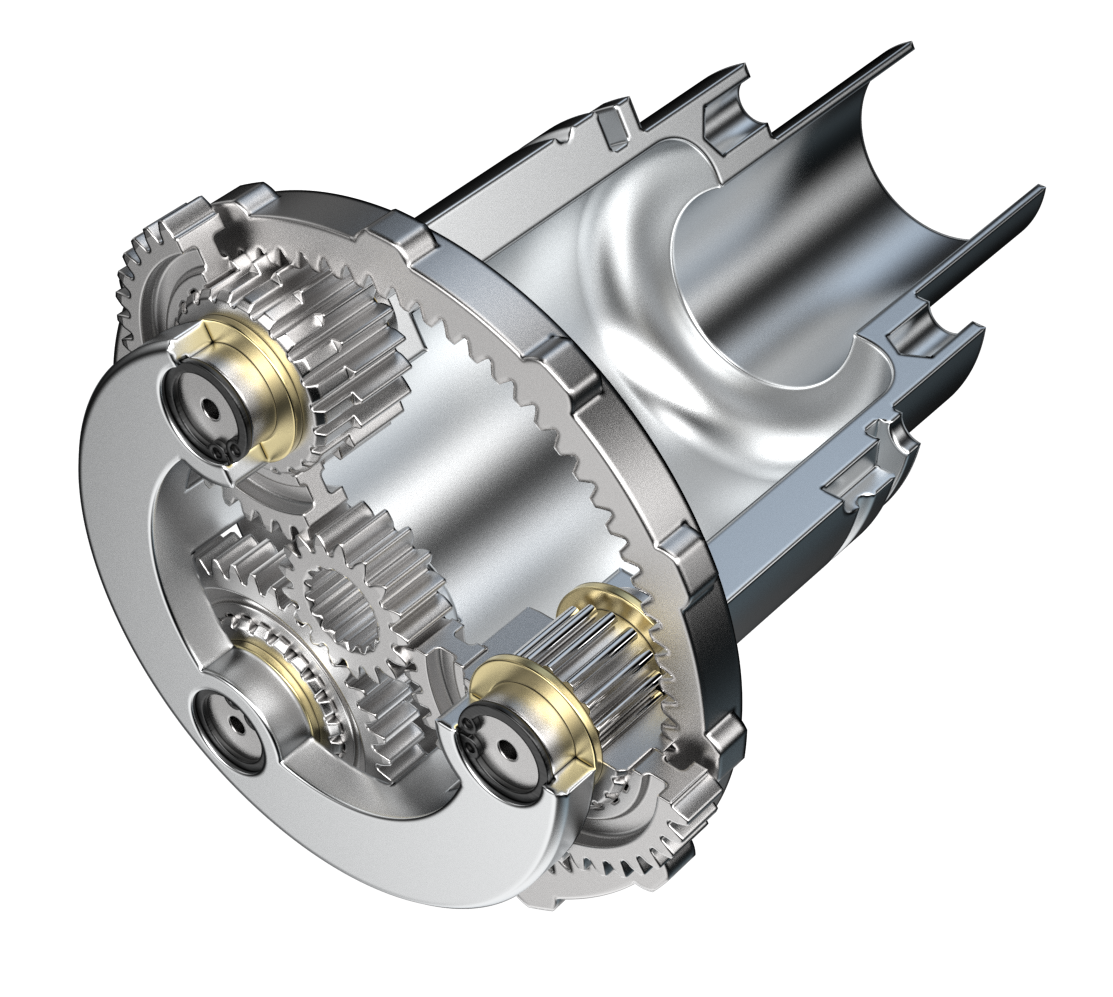

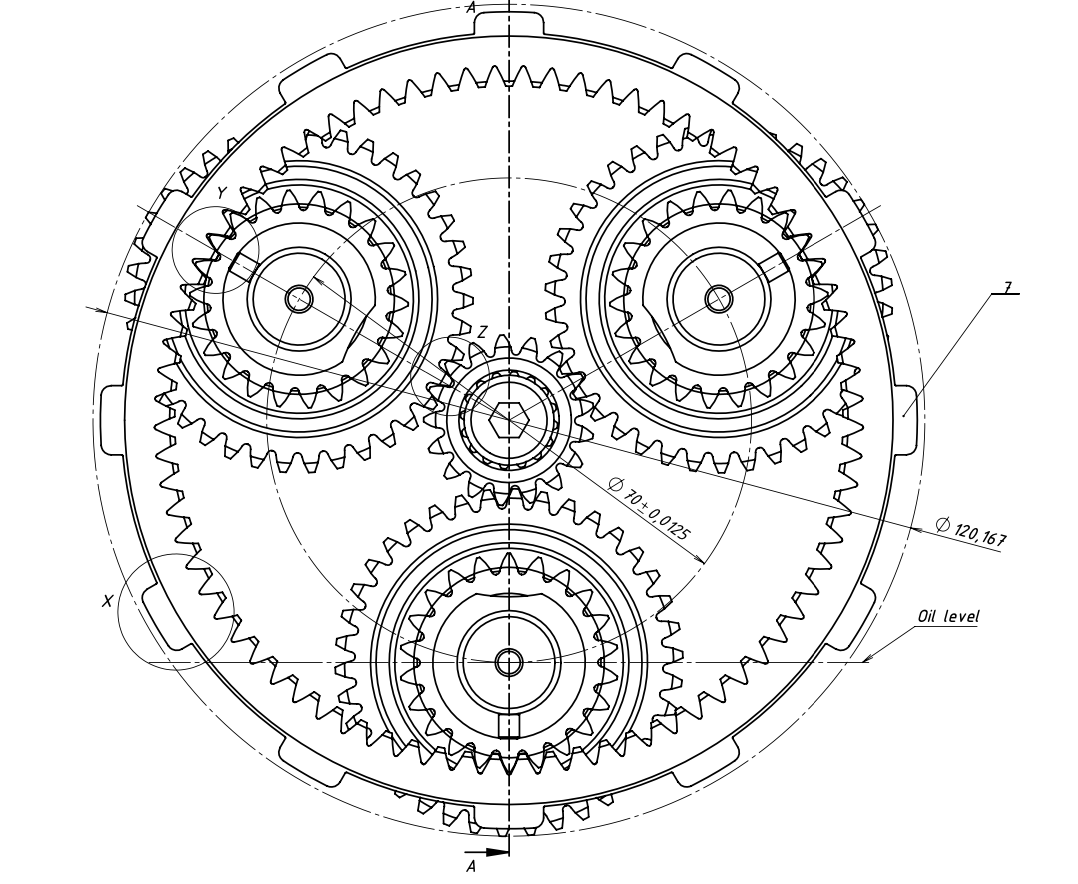

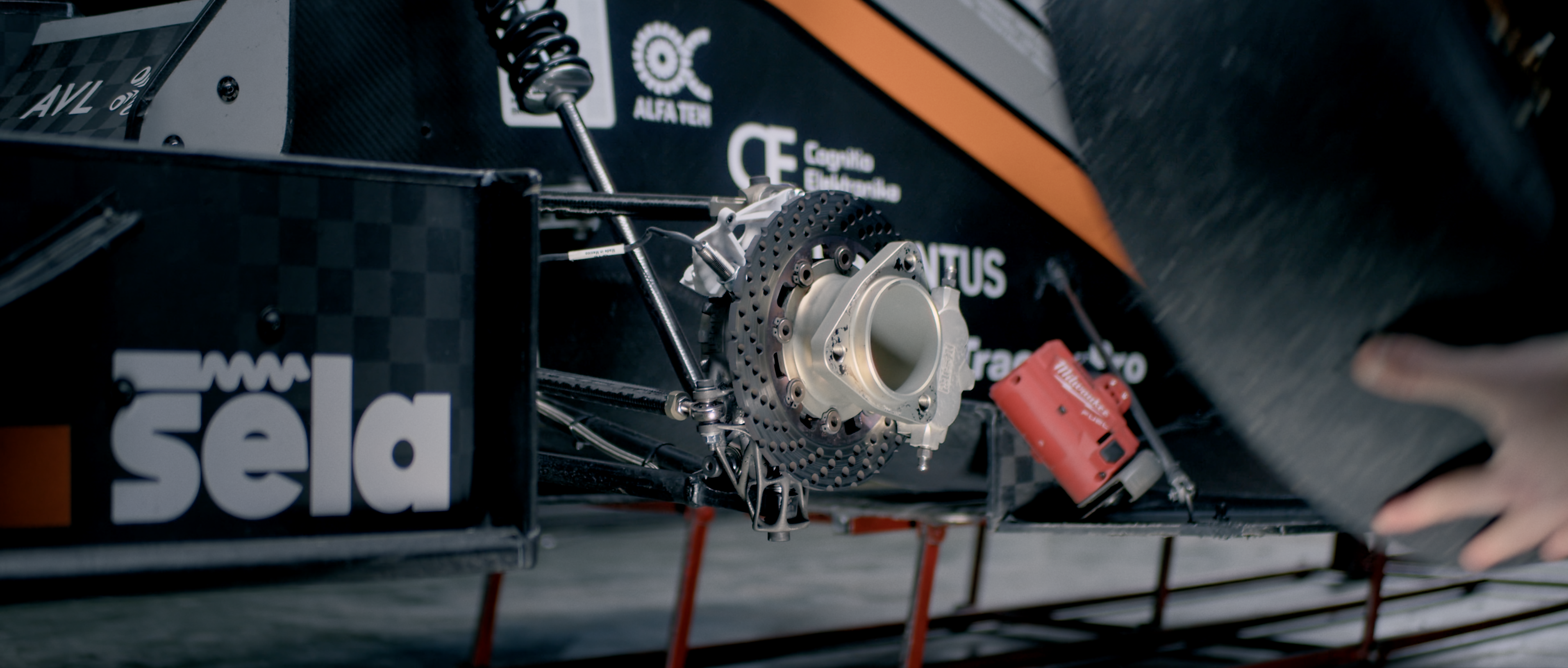

The Drivetrain subteam designs and develops the mechanical side of the vehicle’s powertrain, making iterative improvements to find the most efficient way to transfer torque from the motors to the wheels. A rigorous concept selection process is followed by calculation, modelling, detailing and optimization. Finally, procured standard part and manufactured non-standard parts are assembled.

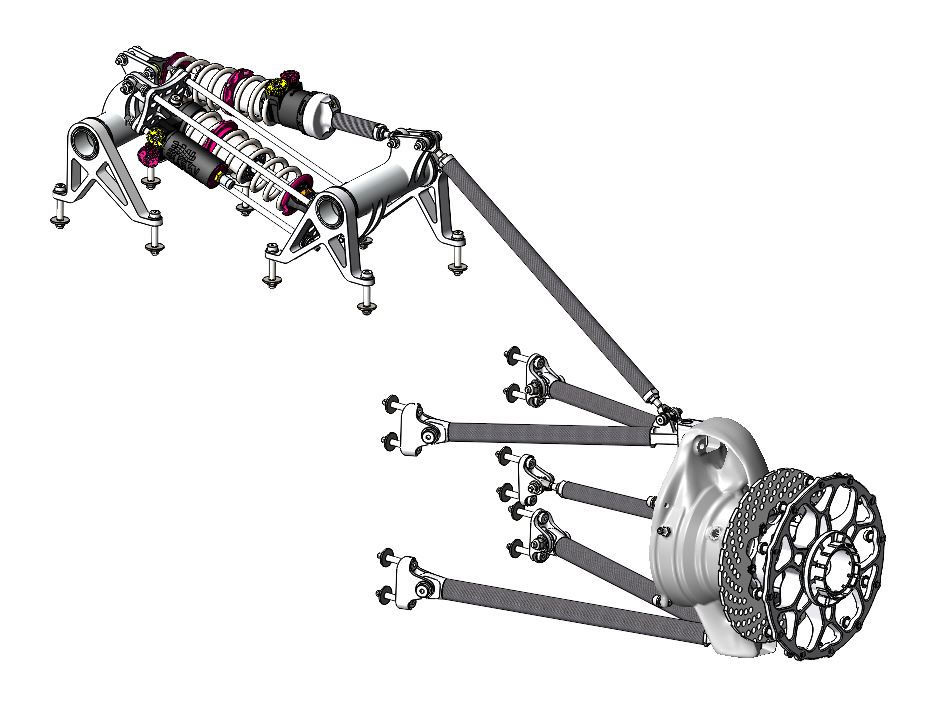

The subteam encompasses the development of the suspension and steering systems from the various concept evaluation to its final assembly and adjustment. To achieve the best vehicle’s performance and ergonomics for the driver, compromises within the subteams have to be made. The team deals with finding lightweight design solutions with high stiffness while satisfying the demanded suspension geometry and packaging, therefore basic knowledge of mechanical engineering, CAD and FEA is required.

- CAD

- Finite Element Analysis

- Topology optimization

- Technical documentation

- Designing

- Concept development

- Framework calculations in Python

- Gear, shaft and bearing calculations in KISSsoft

- Development of CAD models

- FEM analysis of shafts, housings, gears in Abaqus

- Topology optimization of housing and gears in Abaqus

- Model detailing

- Design of suspension parts

- Design of large assemblies (suspension, steering, pedal box)

- Finite element analysis of critical parts

- Finite element analysis of CFRP parts

- Topology and shape optimization

- Assistance in suspension manufacturing and assembling

- Suspension and steering adjustment

- Abaqus

- Python

- Autodesk Inventor

- KISSSoft

- SOLIDWORKS

- MS Office

- CATIA

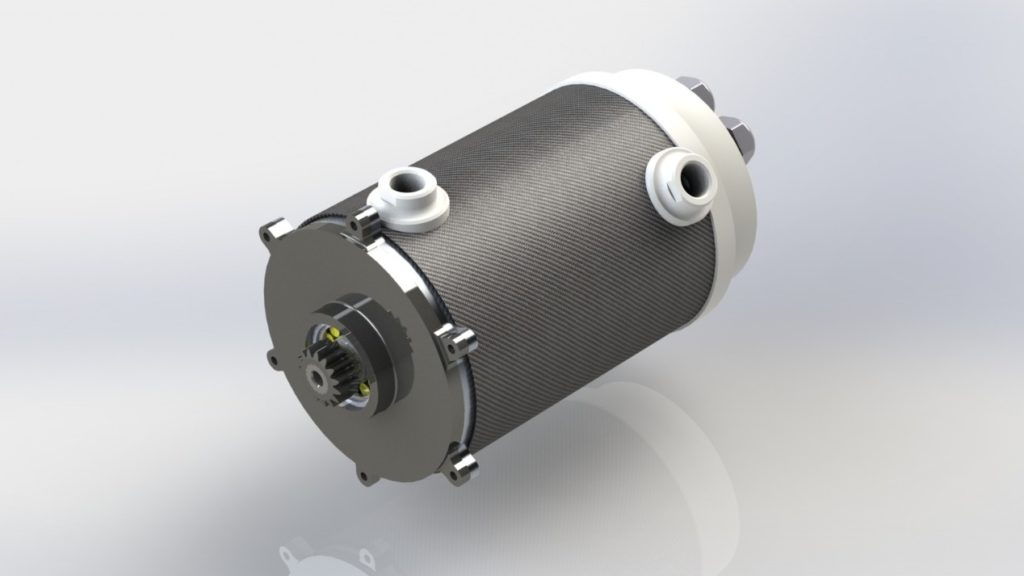

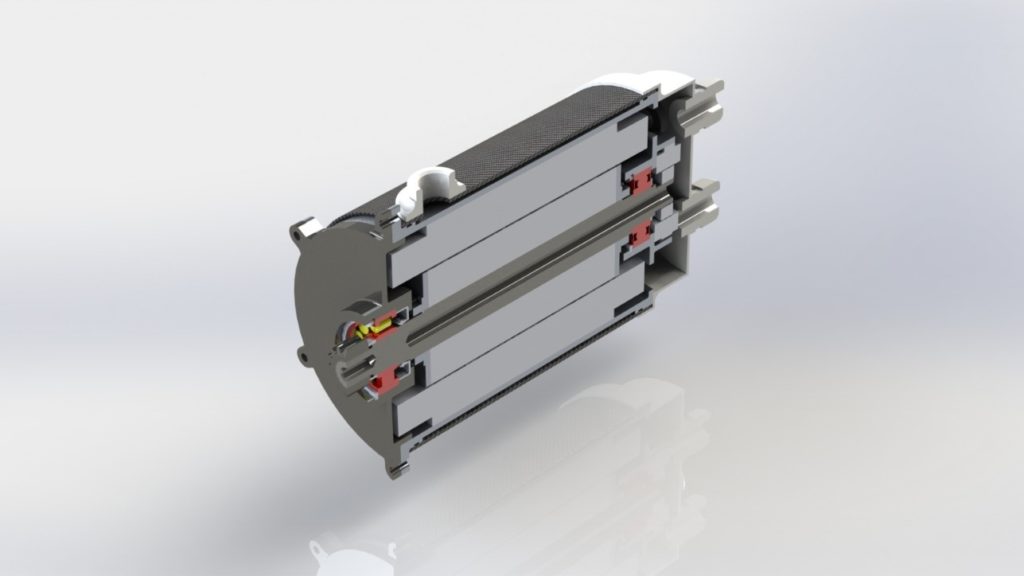

The work in the Electric Motors subteam can be roughly divided into three parts: electrical design, motor design and the modelling and development of the motor cooling system. The development starts with the definition of basic performance that the motors must meet, and the definition of their limit values, followed by the design, manufacturing assembly and extensive testing.

- Electromagnetism

- Finite Element Analysis

- CAD

- Knowledge of material characteristics

- Interdisciplinarity

- Electromagnetism

- - Stator and rotor geometry design

- - Satisfying the requirements of force and momentum

- - Calculation of heat fluxes in the engine

- - Efficiency map calculation

- - Geometry optimization

- Constructio

- - Shaft design

- - Housing construction

- - Bearing selection

- - Selection of sensors and other parts

- SimScale

- Motor-CAD

- SOLIDWORKS

- MATLAB

- Turning

- Lamination

- Milling

- Welding

- Soldering

- Drilling

- All other work in the team garage

- Review of technical documentation of parts forwarded for manufacturing

- Advising members of other sub-teams so that parts are constructed in accordance with the capabilities of production technologies

- Finding machining companies and arranging the manufacturing

- Construction of various devices required for quality team performance (battery trolley, chassis torsional stiffness test device, etc.)

- Improving team's production technologies

- Manufactured parts assembly

- Vehicle assembly

- Technical documentation preparation for static events of FS competitions

- AutoCAD

- SOLIDWORKS

- MS Excel

- Ultimaker Cura

- Prusa Slicer

The Design and Marketing subteams, working as one cohesive unit, collaborate closely to enhance the team’s image and outreach. Design focuses on refining our visual identity through tasks like livery design, UI design, and rendering vehicle components for promotional materials. Meanwhile, Marketing ensures our team is represented effectively by managing sponsor relations, organizing events, and crafting engaging content for social media. Additionally, Marketing takes charge of creating and delivering the Business Plan Presentation (BPP) at competitions, which serves as a comprehensive showcase of our team’s strategy and objectives. Together, these subteams merge creativity with strategy, shaping the team’s brand recognition and ensuring a strong presence both on and off the track.

- Initiative

- Creativity

- Flexibility

- Persistence

- Presentation skills

- Organization skills

- Communication skills

- TA sense of humor

- Defining and improving our PR strategy

- Creating the Business Plan Presentation and defending it at competitions

- Team merchandise purchasing and design

- Communication with sponsors

- Team merchandise purchasing and design

- Communication with sponsors

- Request for bids for the procurement of equipment and materials

- Representing the Team in public at sponsor meetings, team presentations, etc.

- Social networking with other Formula Student teams and other organizations

- Event organization: meetings with sponsors and media, promotional events, and team buildings

- Photographing and recording everything

- MS Word

- MS Excel

- MS PowerPoint

- Adobe Premiere Pro

- CapCut

- Canva

- WordPress

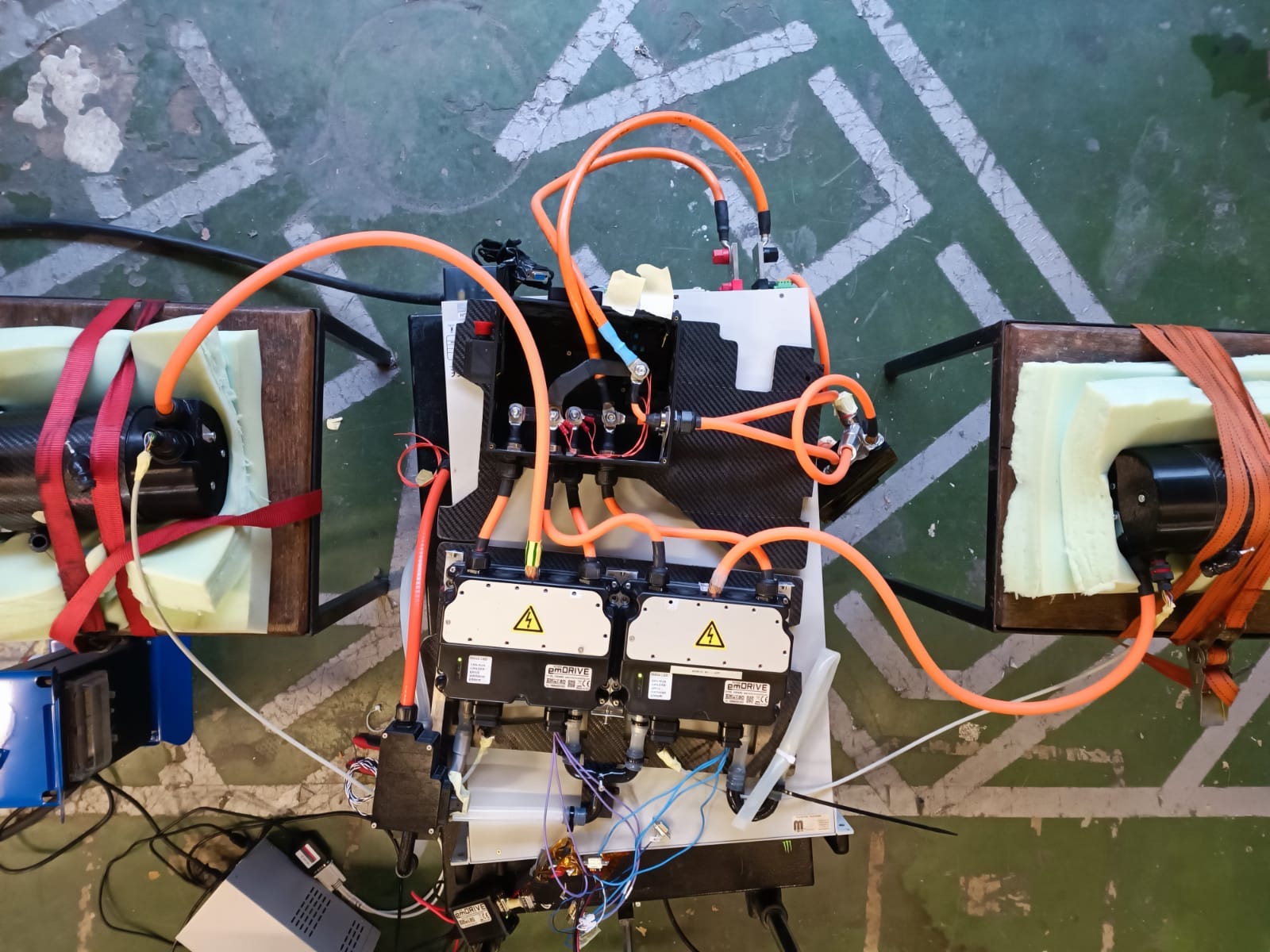

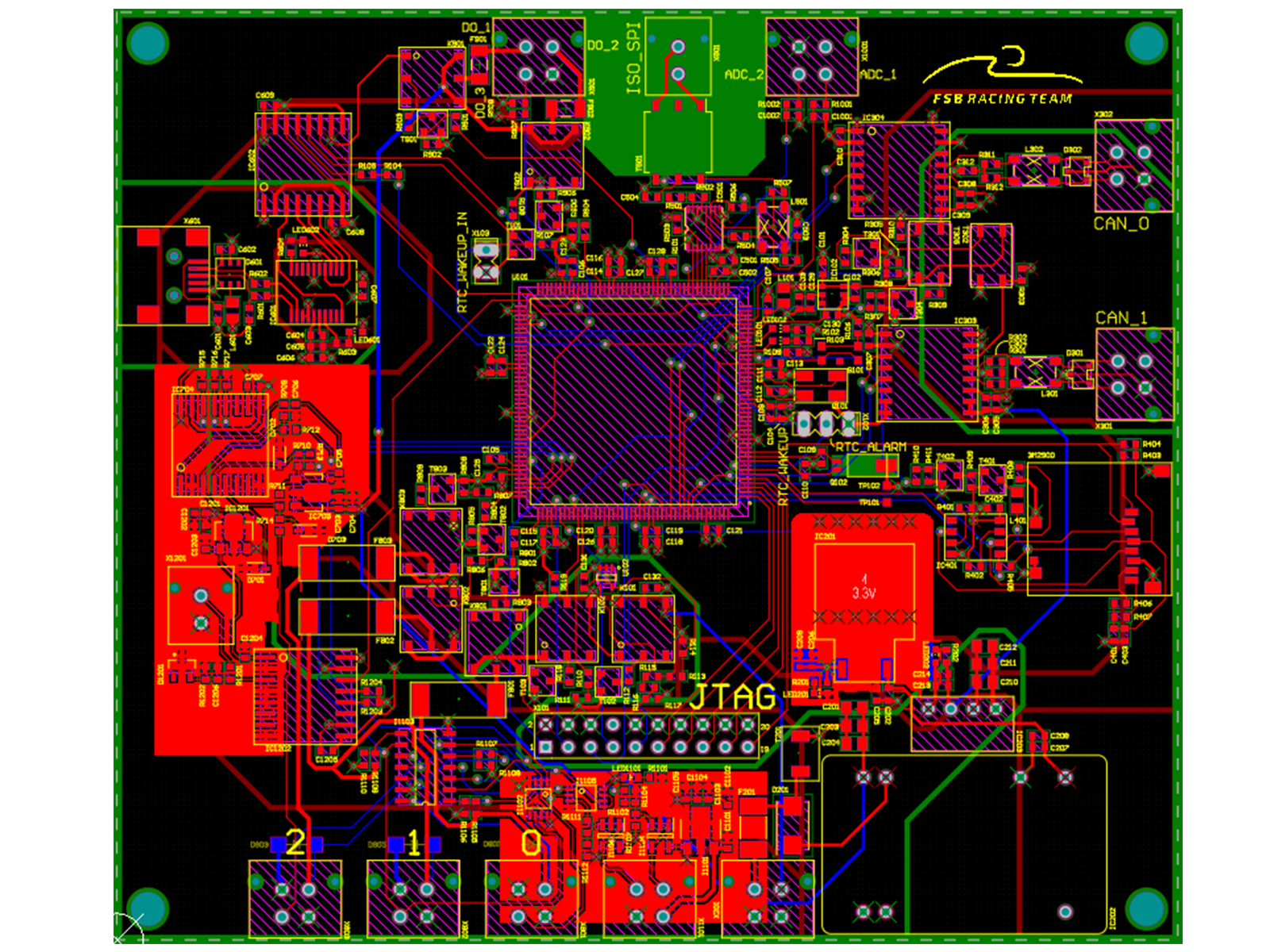

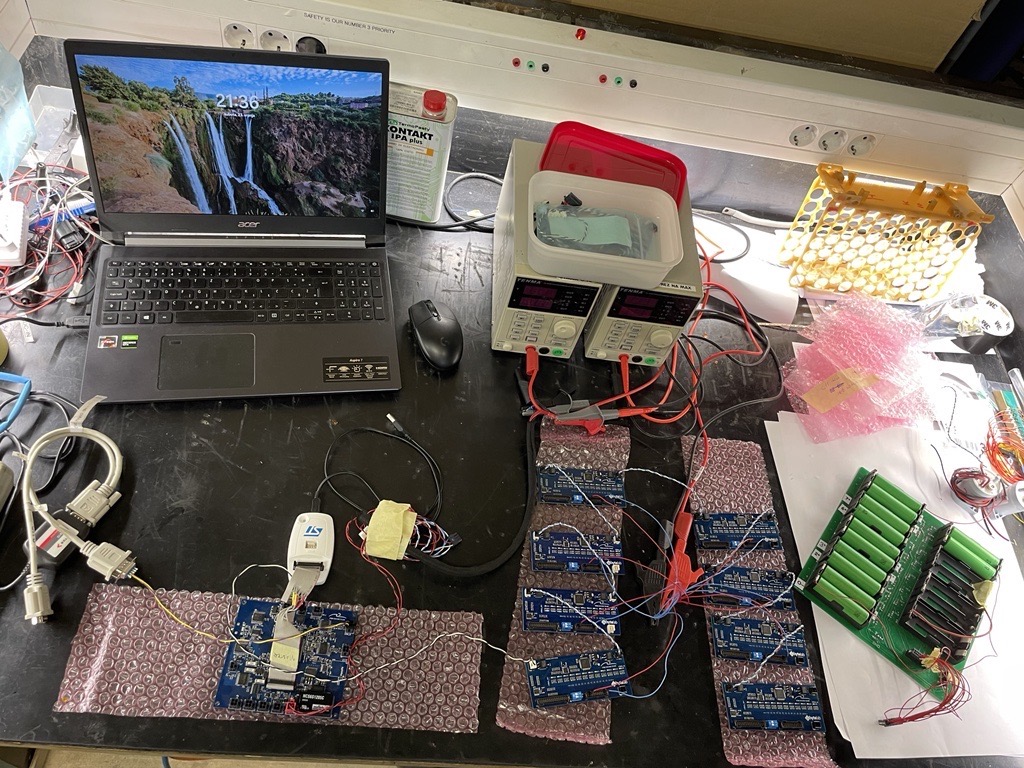

The Powertrain subteam oversees the development of overall electrical architecture of the vehicle, including the development of the battery pack, selection and programming of the inverter, complete HV and LV wiring and electronics systems. The subteam’s main goal is to create an efficient, high-performance, safe and reliable system, thus maximizing the performance of the vehicle.

- Electrical engineering

- Electromagnetic compatibility

- Electronics & wiring

- Soldering

- Understanding CAN & isoSPI communication protocols

- System level troubleshooting

- CAD

- Powertrain concept design

- Battery pack design and manufacturing

- PCB design

- Embedded software development

- BMS development and optimization

- Wiring harness design

- Selection of sensors, cables, fuses, relays

- Testing and troubleshooting on component and system level

- Altium Designer

- Vector CANalyzer

- PEAK PCAN View

- EPLAN Harness proD

- Solidworks

- CST

- Simulink/MATLAB

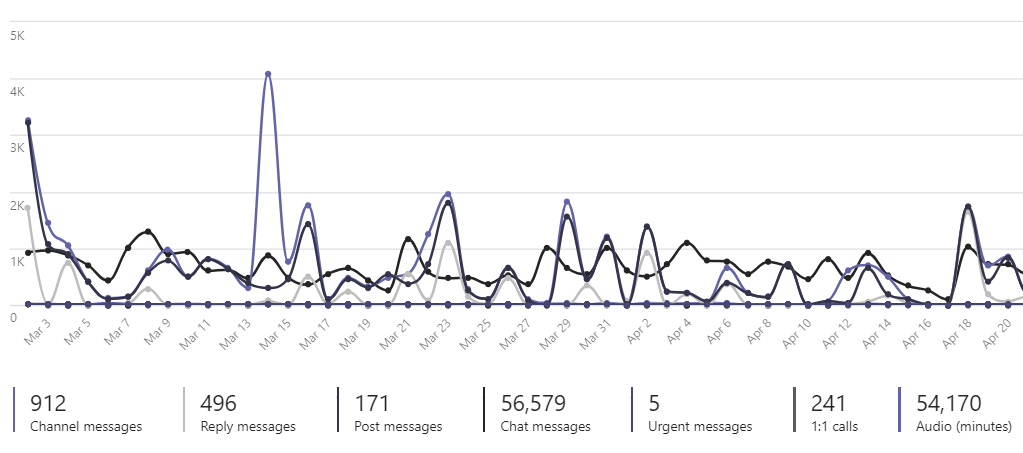

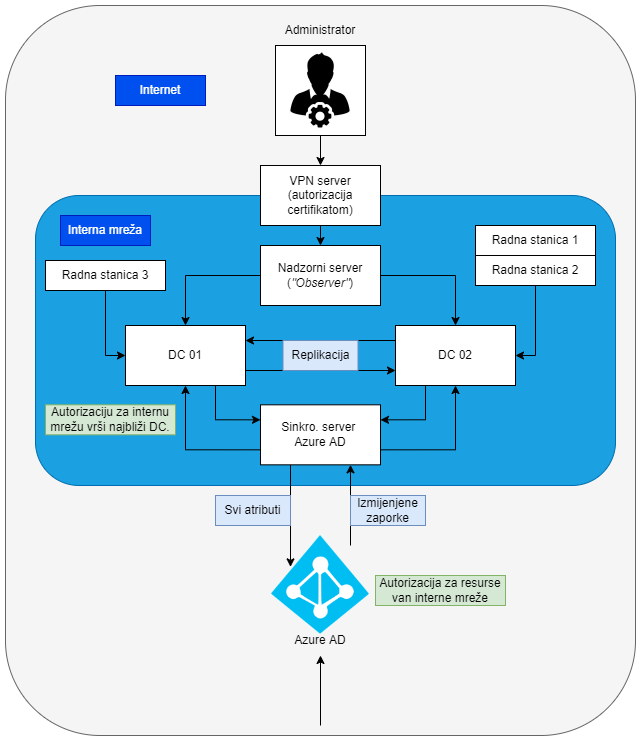

The IT & Systems subteam supports the other subteams by maintaining the systems they need to collaborate and develop on a daily basis, and ensuring that the Team has all the tools it needs to successfully navigate the design phase. We develop custom software solutions for Team’s needs. A hybrid Windows and Linux environment presents special technical challenges that prospective applicants will learn to overcome.

- Abstract problem-solving

- Willingness to learn

- Open minded

- Bulding tailored software

- General Windows & Linux systems administration

- Acquiring thath all team members have access to their software-based needs

- Ensuring high uptime of all services

- Arranging hardware and software solutions

- Wordpress

- Web development - JS stack

- Windows Server

- MS Active Directory & Azure AD

- Proxmox VE