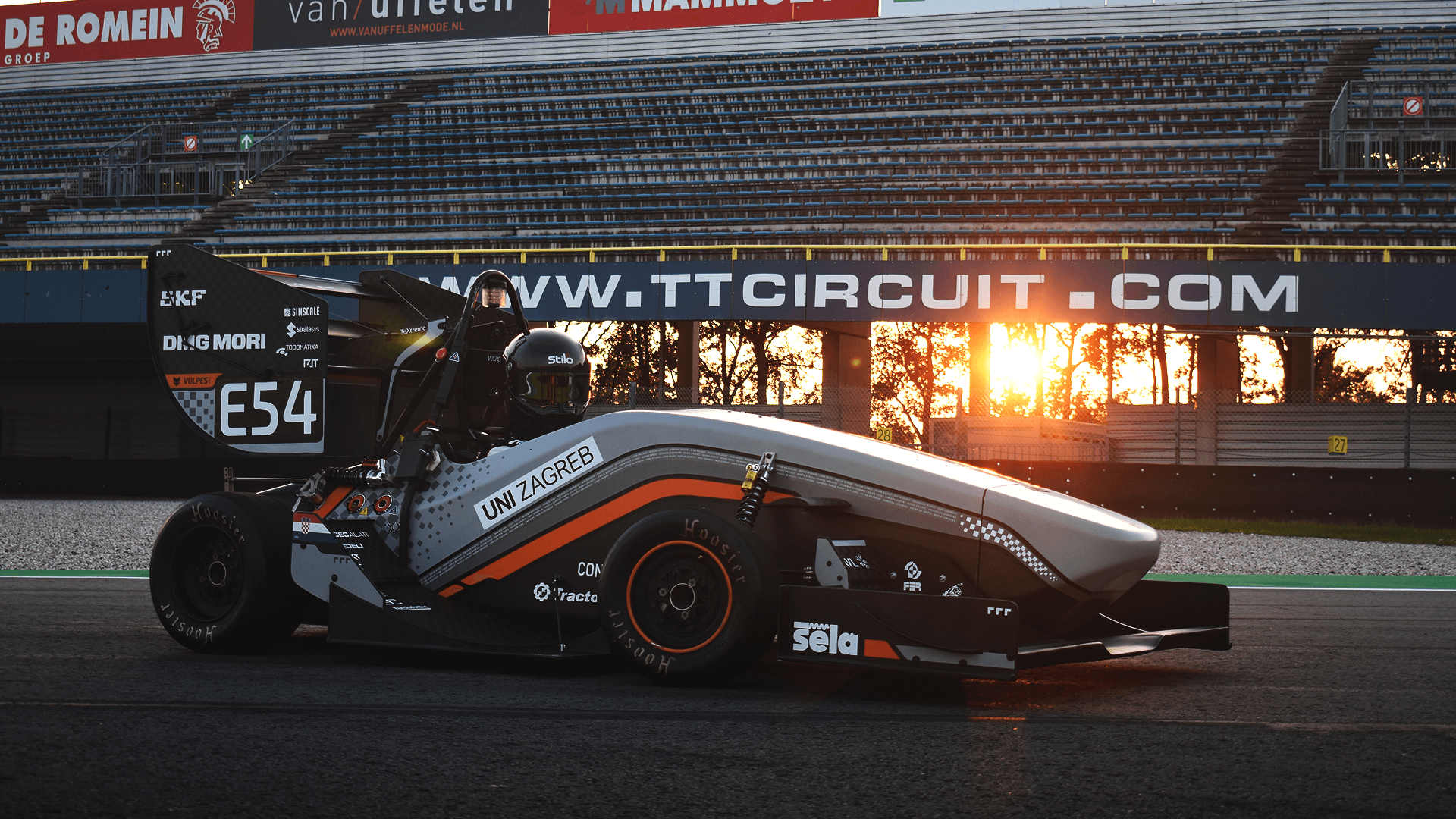

VULPES-R

FSB-RT06

ABOUT VULPESR

We went all-out for the VulpesR- every single one of the Vulpes’s subsystems has been redesigned to lower mass and increase performance. A brand-new telemetry system helps us pinpoint any problems as soon as they arise. The two-stage gearbox was omitted in favor of a single-stage design. The VulpesR pushes the limits of performance in the form of 3D printed sintered titanium uprights and an F1-inspired DRS system.

E-motor: 2 x 40 kW

BMS: In-House Design

Gearbox: Single-speed

Wheel torque: 2 x 480 Nm

Chassis: CFRP Monocoque

Battery: 7.5 kWh

Wheelbase: 1530 mm

Drivetrain layout: Independently Driven

Rear Wheels

MONOCOQUE

The CFRP monocoque, including the roll hoops, weighs 38,3 kg. Based on FEA, we assumed a torsional stiffness figure of 12685 Nm/°, which was revised to 12500 Nm/° after testing. The face skins consist of a combination of 2×2 twill 200 g/m2 and 375 g/m2 CFRP. For the core material, an aluminum honeycomb with a thickness between 15 and 25 mm was used for its specific stiffness, and 25 mm thick PMI foam for its good compression strength.

AERODYNAMICS

The main aerodynamic package goals were to minimize mass, manufacturing cost, and complexity, along with a forward aerodynamic balance shift. To achieve this, side wings were chosen over a complex sidepod geometry, the radiator was placed behind the chassis above the rear diff user, hollow-molded wings were used, and the front-wing carriers and undertray duct geometry were simplified.

SUSPENSION & STEERING

The primary goals during suspension development were increased kinematic adjustability and decreased weight. The car features a pushrod-actuated, unequal-length double wishbone suspension. As the CoG is positioned slightly rearwards, the rear tires are wider, and thus only a rear ARB is used. Weight reduction was primarily achieved by means of FEA. Additionally, CFRP front wishbones and tie rods, as well as SLM, topology-optimized titanium alloy uprights, and rear wishbones saved weight while maintaining or improving stiffness. This resulted in a total suspension system weight of 41,9 kg.

POWERTRAIN

The motors were selected based on targets from longitudinal vehicle dynamics simulations, with the primary goal being to fully utilize the tractive force transferable to the ground. In line with our goal of weight reduction, the aim was to choose a high-speed motor. The final choice was a pair of Alta Motors TM-40 units. They are 60 Nm, 14,000 rpm water-cooled SPM motors, with a dry weight of 6,8 kg resulting in power and torque densities of 5,9 kW/kg and 8,82 Nm/kg. A data-driven choice was made for the TS accumulator cells, where multiple cells were subjected to a test with the FSG track duty cycle. This resulted in the selection of an 18650 type Sony/Murata VTC6 cell. A defined target of 6,8 kWh of usable energy and a 408 V voltage limit imposed by the inverter IGBTs and capacitors resulted in the selection of a 96s7p configuration, divided into six 16s7p accumulator segments.